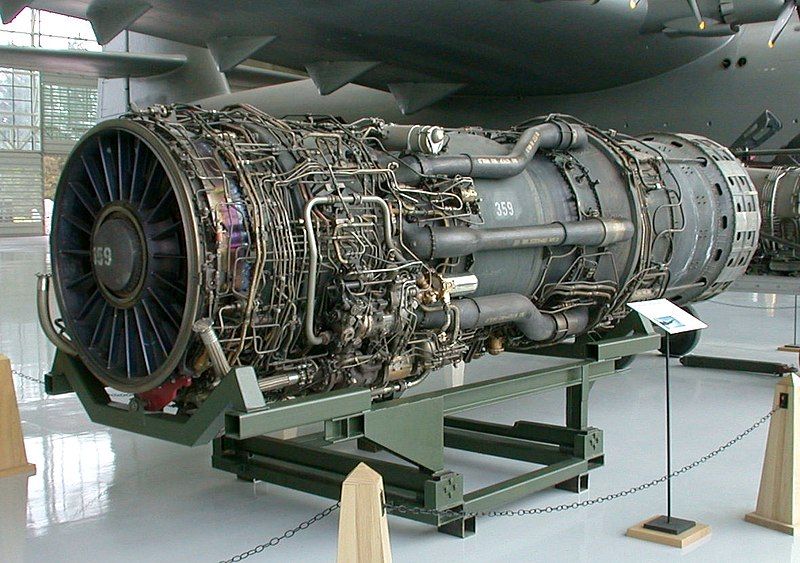

Jet engines are complex machines manufactured with high-precision machining to ensure optimal performance. Modern jet engines are more powerful than ever, offering sufficient power and fuel economy for some of the largest airliners. This article explores some interesting facts about modern jet engines.

1

Modern engines use additive manufacturing

Many parts are 3D-printed to reduce weight

- VAT Photopolymerisation

- Material Jetting

- Binder Jetting

- Material Extrusion

- Powder Bed Fusion

- Sheet Lamination

- Directed Energy Deposition

Modern aircraft engines use advanced manufacturing and processing techniques to achieve precision, accuracy, and weight savings. One such technique is additive manufacturing, where many engine parts are 3D-printed using a range of materials, including composites. According to GE Aerospace,

“More than 40 additive machines operate 24/7. Within them, highly complex fuel nozzles grow layer by layer, as a very thin coating of powdered metal is fused by extremely precise lasers. The result is a lighter, more durable single-piece nozzle that replaces up to 25 parts, compared to traditional manufacturing methods.”

Photo: CFM International

Such components are easy to produce, cost-effective, and lighter in weight, significantly minimizing production and operating costs.

2

Engines have live-monitoring capability

Advanced Health Monitoring Systems

- Aircraft health monitoring

- Aircraft real-time visualization

- Event analysis dashboard

- Troubleshooting Manual (TSM)

- Prioritize and plan

- Faster AOG resolution

Modern engines are equipped with advanced health monitoring systems—computerized systems that utilize specialized sensors, accelerometers, and cameras to monitor the engine’s health in flight. The live monitoring of the engines ensures that all parameters run within prescribed limits.

Any deviation is recorded, and troubleshooting procedures are enabled. The system also aids in preventive and on-condition maintenance schedules. According to Airbus,

“In-flight events generate unscheduled maintenance and have a huge impact on the availability of the fleet, therefore generating costs. Skywise Health Monitoring makes sure you can manage these events efficiently and in real-time to ensure an efficient dispatch.”

3

Very high temperatures

Maximum Internal temperature: 3,500 F (2,000 C)

- Combustion chamber

- Fuel nozzles

- Turbine nozzles

- Turbine blades

- Stator vanes

Modern jet engines are designed to produce immense thrust levels, offering sufficient power for large aircraft. High power requirements mean engine components run at very high temperatures, up to 3,500 degrees Fahrenheit. For example, the combustor chamber and engine nozzles are some of the hottest components of the engine. They require efficient cooling techniques during operation.

Photo: Rostec

A Stanford University blog states,

“In the combustion chamber, fuel is mixed with air to produce the bang, which is responsible for the expansion that forces the air into the turbine. Inside the typical commercial jet engine, the fuel burns in the combustion chamber at up to 2000 degrees Celsius. The temperature at which metals in this part of the engine start to melt is 1300 degrees Celsius, so advanced cooling techniques must be used.”

4

A range of internal cooling methods

Turbine blades require several types of cooling mehods

- Convection cooling

- Impingement cooling

- Film cooling

Normal convection cooling occurs as a result of heat being transferred from the blade to the surrounding environment, in this case, air. The impingement cooling method enables a relatively high-velocity spray of cold air along the surface of the blades. Depending on the cooling requirements, the air pressure and velocity can be controlled in impingement cooling.

Photo: CFM

Film cooling is a technique in which (relatively) cold air is inserted through small holes in the blades. The air creates a thin layer along the surface, acting as an insulating blanket. The blade’s cooling effectiveness is measured on a scale of 0 to 1. The actual value determines the temperature difference between the blade wall (having the thin film) and the surface temperature.

5

Redundant systems

Dual channel philosophy

- One active channel

- One standby channel

- Different procedural logic depending on the occurrence

- Channels are generally automatically switched on every startup

Aviation systems and components are designed to be redundant, particularly those critical to the aircraft’s safety and performance. Jet engines are no different regarding the redundancy of components and systems. Modern engines have a dual-channel philosophy attached to every critical component and system.

Photo: Virgin Atlantic

For example, if Channel A acts as the active channel, Channel B will work as the standby channel. If a malfunction occurs on a component level, such as a temperature sensor, the sensor information is transferred from Channel B. The channels are switched if a malfunction occurs on a system level, such as a variable bleed valve mechanism. The malfunctioning Channel A goes to standby while the working Channel B becomes the active channel. This philosophy ensures the safety of the aircraft and its occupants.