Summary

- Jet engines work on the “suck, squeeze, bang, blow” principle, using highly pressurized air and fuel combustion to generate thrust.

- Engine materials have evolved from steel to nickel-chromium superalloys, with advanced cooling techniques and atomic structure engineering for high-temperature performance.

- Modern turbofan engines balance fuel efficiency with weight, using larger fans and composite materials for increased bypass ratio and reduced weight.

Jet engines are complex machines that have revolutionized the aviation industry with their sheer size, aerodynamic structure, and fuel efficiency. Modern jet engines are manufactured with composite materials and advanced manufacturing techniques to minimize weight and achieve fuel savings for operators. The power delivered by these revolutionary engines has allowed humans to fly further, faster, and cheaper than ever before. But how do these engines work?

The gas turbine engine

Turbofan engines power many modern commercial aircraft. They are part of a family of engines called gas turbines, including engines for some helicopters, smaller powerplants, and even some types of tanks.

The name turbine gives some clue as to how this type of engine functions. Other turbines, such as wind or steam turbines, all rely on something spinning to generate power. Gas turbines are no different. While wind spins a wind turbine and steam drives a steam turbine, another type of pressurized gas spins a gas turbine—air.

Gas turbines must produce this highly pressurized air to ensure power flow to the engine. They do this by burning something very energy-dense, like jet fuel, kerosene, or natural gas. Burning the fuel expands the air, and this rush of hot air causes the turbine to spin.

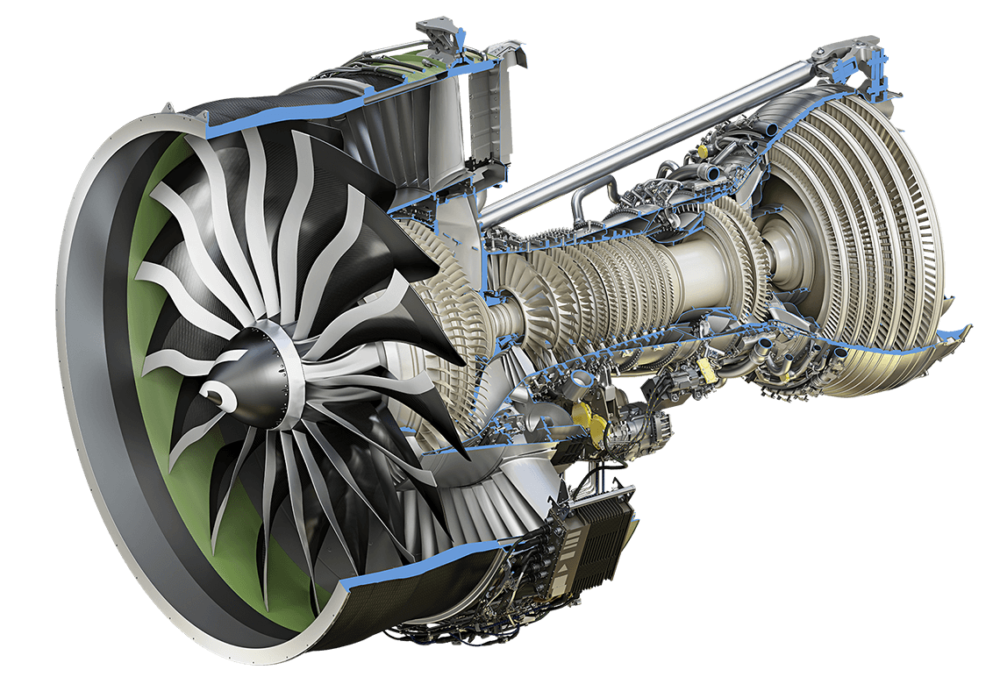

Photo: GE Aerospace

Jet engine working principle

- Suck: Large amounts of air from the atmosphere

- Squeeze: The air through a series of compressor stages

- Bang: Ignite the compressed air with atomized fuel

- Blow: The hot air through the exhaust to generate thrust

The process by which this happens is sometimes bluntly explained by the concept of ‘suck, squeeze, bang, blow.’ Air is sucked into the engine from the front using the big fan visible when looking at a plane straight on.

The air is then compressed in the next stage of the engine—this is the ‘squeeze’ part. A second fan increases the pressure in the air by around eight times, which also significantly increases its temperature.

Fuel is mixed with the air and ignited—bang—producing power. This hot, high-pressure air rushes past a set of turbine blades, causing them to spin. This turbine is connected by an axle to the compressor and the fan, so as the gases turn the turbine, this causes both the inlet fan and compressor fan to spin, too.

Finally, the hot exhaust gases exit the engine via a tapering exhaust nozzle. Just as putting your thumb over the end of a hosepipe (reducing the exit aperture for the water) causes water to squirt out at high speed, this tapered exhaust speeds up the exiting gases. The hot air leaving the engine moves at over 2,100 km/h (1,300 mph), around twice the speed of the cold air entering the front.

Photo: GE Aerospace

It is this rapidly moving air that pushes the vehicle forward. Military jets (and one very special passenger plane) sometimes use afterburners, which are simply fuel squirted directly into the exhaust jet to create additional thrust. But for most passenger planes, the shove from the moving air is more than enough to provide sufficient forward motion for their wings to generate lift.

Related

How Do Jet Engine Startup Procedures Work?

A long list of pre-startup checks must be completed before starting the engine(s).

Perfectly simple?

Sounds simple enough? Essentially, it is, but the pressures and high temperatures make designing jet engines a rather specialist task. In the combustion chamber, where the compressed air is mixed with the fuel, the burning temperatures reach more than 900 °C (1,650°F).

This means that engines need to be made from strong yet lightweight, thermally stable and corrosion-resistant components that will not bend, break or become weak under extreme heat and pressure. In the early days of the jet engine, Sir Frank Whittle’s prototypes relied on steel. This was a strong and hard material, but would not cope with the stresses of the modern gas turbine. Steel begins to degrade at around 500 °C (932 °F).

Photo: GE Aerospace

The unsuitability of steel meant engine manufacturers needed to look for another type of material. The Goldilocks metal manufacturers settled on nickel with some chromium mixed in. It was light, cheap, and strong. It resisted corrosion and would retain its integrity to 85% of its melting point, a staggering 1,455 °C (2,651 °F).

These early superalloys made jet engines cheaper, more efficient, and far easier to mass-produce. Descendants of this mix still provide the structure in the hottest part of the gas turbine engine, operating at temperatures of as much as 1,700 °C (3,000 °F), somewhat higher than the metal’s melting point. So, how do engine manufacturers ensure the integrity of these parts?

Related

How Much Do Jet Engines Cost?

A jet engine can cost between $50,000 and $50 million depending on the size and power capability.

Cool your jets

The first strategy is to apply a ceramic coating, which reduces heat penetration. Secondly, cool air is fed to the surface of the blades, drawn from further up the engine, and distributed by tiny holes in the blade’s surface. In an interview with The Engineer, Rolls-Royce chief of materials Neil Glover explained,

“The blades operate in an environment several hundreds of degrees hotter than the melting point of the nickel alloy, but because of the cooling mechanisms, the metal is never above its melting point, even though the environment is.”

Photo: Rolls-Royce

Materials technology has gone even further than this, rearranging the metal’s atomic structure to avoid losing integrity. The tiny crystals that make up metals are engineered to grow all in the same direction to eliminate the weaknesses usually found at the boundaries of the crystals. This means the blades are like a gemstone, with a single atomic lattice right through their structure.

Over the years, the nickel alloys have been refined further by creating new mixes and adding new elements. This gives the turbine designer the opportunity to create the perfect mix for each engine component.

Photo: Pratt & Whitney

A balancing act

As engine designs have evolved and improved, turbofan engines have typically increased. This is because most thrust results from incoming air diverted around the compressor and turbine. The difference in the air volume delivered to the turbine versus that which is diverted around it is known as the ‘bypass ratio.’

This ‘bypass thrust’ does not require fuel to be burned directly. As such, engine efficiencies have been improved by increasing the bypass ratio, creating a larger diameter engine. But there’s a downside to this, too. Making the engine larger means making the fan sections larger, which makes for a heavier engine. Every extra kilo of weight in the fan section requires 2.25 kg of additional support structure in the engine and wing.

To mitigate some of the increased weight of more fuel-efficient engines, manufacturers have started to turn to composite materials as a replacement for metals. Ceramic matrix composites are as tough as metals but just a third of the weight of nickel alloys.

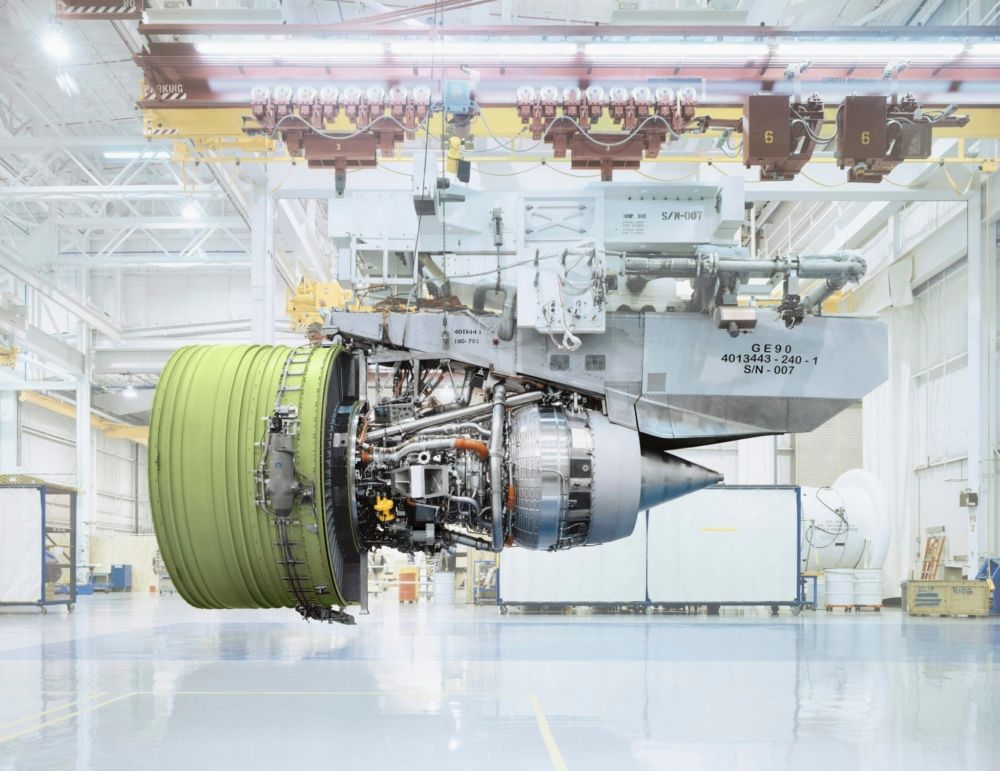

Photo: GE Aerospace

The world’s largest engine, the GE9X for the 777X, uses composite materials in the fan blades and case. It also uses ceramic matrix composites in the turbine and combustor. This large, light, and strong engine promises to be 10% more fuel-efficient than its predecessor, the GE90 and is also the quietest engine ever produced by GE.

Related

GE90 vs GE9X: Which Boeing 777 Engine Type Is Most Powerful?

Despite being larger and more capable, the GE9X is rated at a lower thrust than its predecessor, GE90.