Summary

- GE Honda Aero Engines collaborates with GE Aerospace and Honda Aero to manufacture engines for light jets.

- The HF120 engine has advanced features like a 24:1 pressure ratio, reduced emissions, and lower operating costs.

- The HF120 engine is designed for efficiency and durability, supporting the HondaJet’s payload capacity and range.

GE Honda Aero Engines, formed in 2004, is a joint venture between GE Aerospace and Honda Aero. The company aims to manufacture low-thrust class (1,000 to 3,500 lbf, 4.4 to 15.6 kN) engines for business aircraft. According to GE Aerospace,

“Two of the world’s most respected names in propulsion have come together to design and manufacture engines for the next generation of very light jets. The joint venture, GE Honda Aero Engines, combines the strengths of two industry leaders recognized for delivering high performance and reliability.”

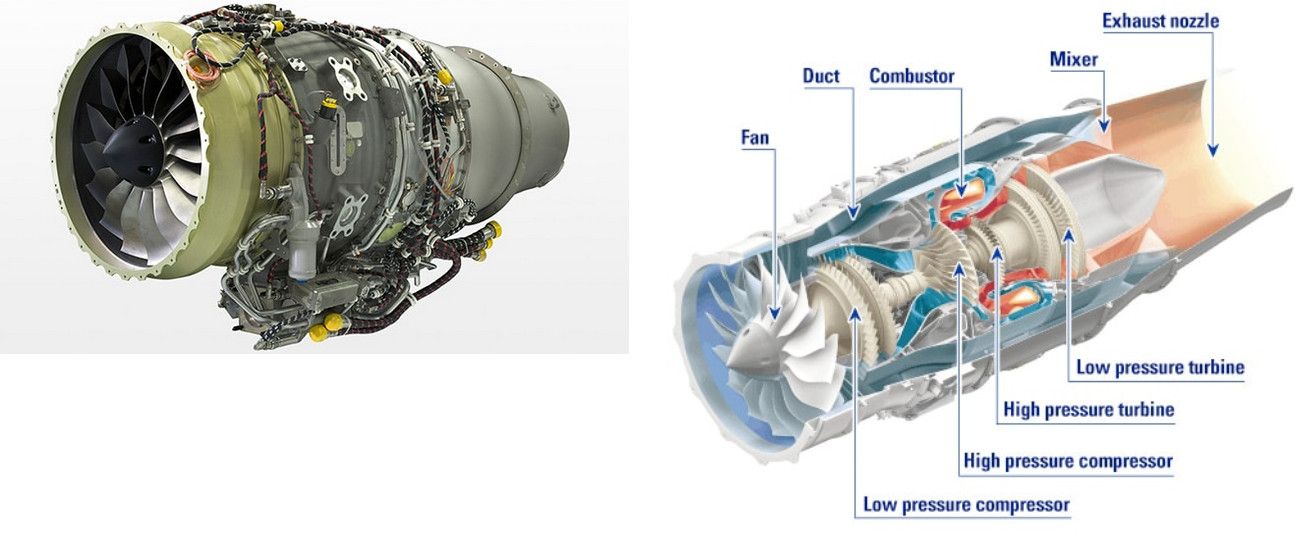

The HF120 turbofan engine

General characteristics

- Length: 59.5 in (151 cm) (end-to-end)

- Diameter: 25.8 in (66 cm)

- Dry weight: 211.3 kg (466 lb) with basic accessories and optional equipment

- Compressor: One wide-chord fan, two axial LP stages, and one centrifugal HP stage.

- Combustor: Compact reverse flow annular

- Turbine: One axial HP stage (48,777 rpm), two axial LP stages (19,055 rpm)

Performance characteristics

- Maximum thrust: 2,050 lbf (9.1 kN) (Takeoff)

- Overall pressure ratio: 24:1

- Bypass ratio: 2.9:1

- Turbine inlet temperature: 1,580 °F (860 °C) (Takeoff)

- Specific fuel consumption: <0.7 lb/lbf/h (71 kg/kN/h)

- Thrust-to-weight ratio: 4.4

Photo: HondaJet

The HF120 is the first engine produced by the company, capable of producing 2,050 lbf (9.1 kN) of takeoff thrust. The HF120 was developed from Honda’s original HF118 prototype, produced at the GE factory in Cincinnati, Ohio. The engine received the Part 33 certification by the Federal Aviation Administration (FAA) in 2013 and production certification in 2015.

Related

How Much Does It Cost To Own & Operate A HondaJet?

If you are budgeting for a private jet next year and a HondaJet is in your sights, this might help you steer in the right direction.

According to GE Aerospace,

“The HF120 engine, the first product from GE Honda Aero Engines, epitomizes the strengths of GE Aerospace and Honda — advanced manufacturing, significant R&D investments, technology leadership, and strong commitment to customers. The engine is designed to deliver unparalleled performance, reliability, and value to business aviation.”

The engine consists of a two-stage low pressure (LP) compressor and a single stage high pressure (HP) centrifugal compressor. The effusion-cooled combustor design allows for greater operational efficiency and lower environmental footprint. The HF120 engine generates significantly low carbon dioxide and nitrogen oxide.

The HF120 design enhancements

A turbofan engine is typically constructed as a modular design, split into four or five core modules: fan module, compressor module (including combustor), high-pressure (HP) turbine module, low-pressure (LP) turbine module, and external gearbox module. GE Honda Aero Engines produced the state-of-the-art design by excelling in all engine modules.

Photo: Honda

Moreover, within the HP compressor section, modern fabrication and processing techniques optimize engine efficiency while minimizing carbon and noise footprint and increasing time between overhauls. Some improvements in each module highlighted by the GE Honda Aero Engines are listed here.

Fan module

- Wide chord, compound swept fan blades for higher efficiency

- Blisk design (bladed disk) for lower noise & damage tolerance

Air and fuel mixing

- Lightweight design (use of composites)

- Advanced geometry for optimal air mixing

- Designed for noise reduction

Related

4 Notable Features Of The Honda HA-420 HondaJet

Early concepts of the aircraft date back to the late 1990s.

Combustor

- Compact, reverse-flow design (reduced pressure loss, greater efficiency)

- Effusion cooling for maximum durability

Compressor

- Single-stage titanium impeller

- Increased engine pressure ratio

HP turbine module

- Low shock, 3D aero design

- Single crystal blade materials

- Commercially proven reliability

LP turbine module

- Counter-rotating design

- Fewer parts, resulting in reduced weight

Photo: Oleksandr Naumenko | Shutterstock

With a wide range of enhancements on the original Hf118 prototype, and continuous improvements have enabled the HF120 to have lower operating costs and remain on wing 40% longer than similar engines. Longer time between overhauls also means greater operational reliability and fewer interruptions.

GE Aerospace claims that the design directly affects maintenance costs, particularly those caused by foreign object damage. The engine features an increased damage tolerance thanks to the durable yet lightweight design. The manufacturer claims the engine’s high thrust-to-weight ratio enables greater speed and reduced climb time to the cruising altitude.

The innovative design of the HondaJet is well supported by the HF120 engine, providing best-in-class durability and fuel efficiency. Greater aircraft payload is supported economically, and longer range is made possible through the three-dimensional aerodynamic design.

According to GE Honda Aero Engines,

“By reducing weight and incorporating innovative 3D aerodynamic designs, the HF120’s components interact with greater efficiency while optimizing operability. The engine uses a centrifugal impeller designed to operate at state-of-the-art aerodynamic efficiency levels without the need for variable geometry. This is complemented by a unique, effusion-cooled combustor design to deliver exceptional environmental benefits.”

Related

The Plane With Pylon-Mounted Engines: A Brief Guide To The Honda HA-420 HondaJet

The business jet has received numerous accolades for its groundbreaking design and technology

What are your thoughts on the joint venture between GE Aerospace and Honda Aero to develop the first engine powering the HondaJet? Share your views in the comments section.