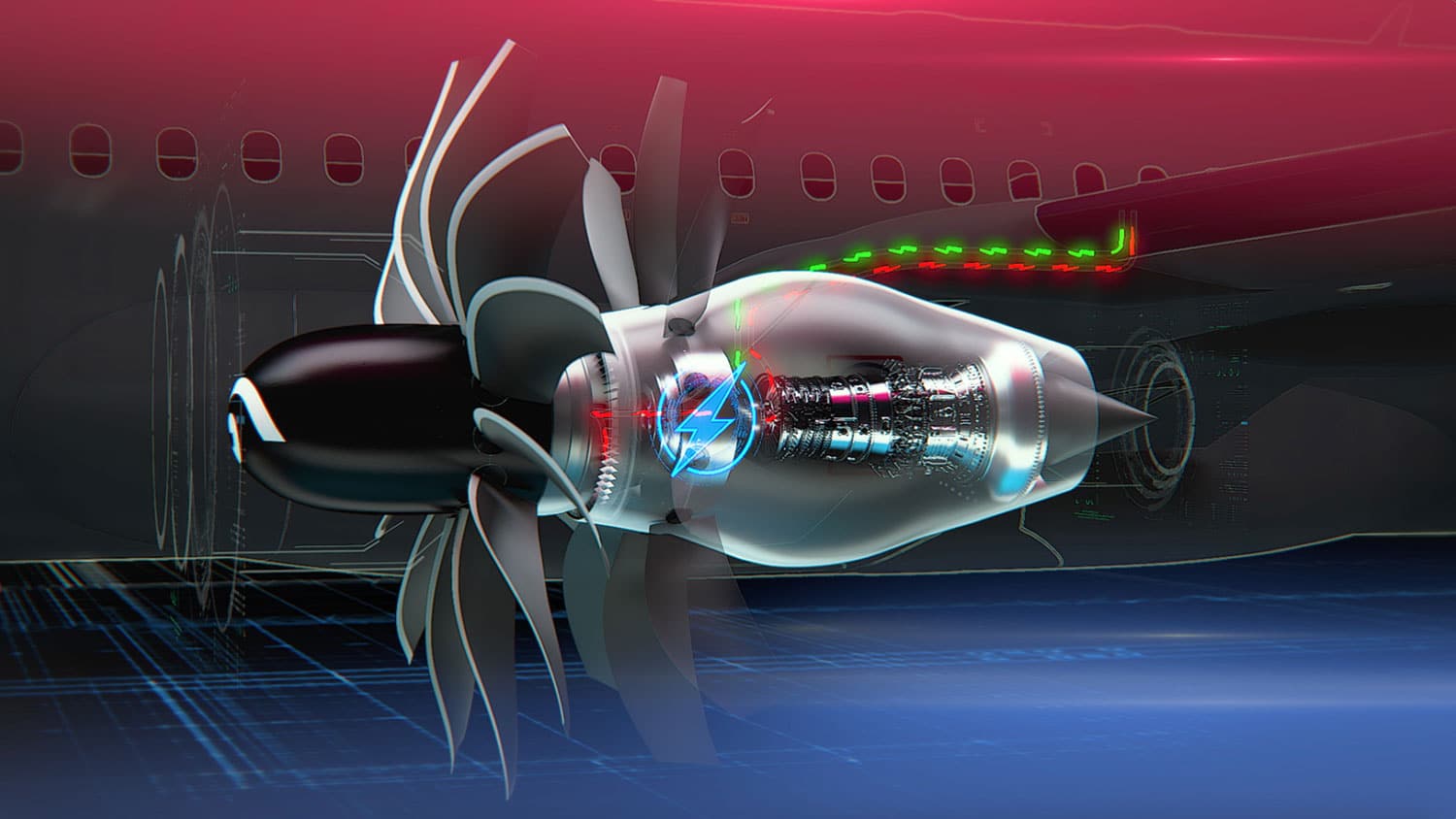

NASA and industry partners are embarking on the next phase of designing a cutting-edge jet engine concept for the next generation of highly efficient airliners.

With a focus on sustainability, NASA aims to develop a small core for a hybrid-electric turbofan jet engine, potentially reducing fuel burn by 10% compared to current engines. This innovative approach to shrinking the engine core can significantly enhance fuel efficiency and contribute to a reduction in carbon emissions.

The HyTEC project aims to showcase a compact core and prepare the technology for integration into the engines of next-generation aircraft by the 2030s. HyTEC is a key element of NASA’s Sustainable Flight National Partnership.

The project is divided into two phases: Phase 1, which is nearing completion, focused on the selection of component technologies for the core demonstrator. Phase 2, commencing now, will involve the collaborative design, construction, and testing of a compact core with GE Aerospace.

“Phase 1 of HyTEC is winding down, and we are ramping up Phase 2,” said Anthony Nerone, who leads HyTEC at NASA’s Glenn Research Center in Cleveland. “This phase will culminate in a core demonstration test that proves the technology so it can transition to industry.”

Before commencing the design and construction of the core, researchers delved into the exploration of cutting-edge materials for the engine. After three years of remarkably swift progress, HyTEC researchers devised innovative solutions.

“We have maintained unwavering focus from the outset. We established specific technical objectives and success metrics for the project, and thus far, we have not deviated from any of them,” Nerone stated.

To reduce the size of the core while preserving the same level of thrust, heat, and pressure must be increased compared to conventional jet engines currently in use. This necessitates the use of more resilient materials capable of withstanding higher temperatures in the engine core.

In addition to materials research, the project also delved into advanced aerodynamics and other crucial technical components.

Phase 2 builds on Phase 1 to create a compact core for ground testing that proves HyTEC’s capabilities.

“Phase 2 is very complex. It’s not just a core demonstration,” Nerone said. “What we’re creating has never been done before, and it involves many different technologies coming together to form a new type of engine.”

The technologies being tested in the HyTEC program have the potential to significantly increase the bypass ratio, enable hybridization, and ensure compatibility with sustainable aviation fuels.

The bypass ratio refers to the relationship between the volume of air passing through the engine core and the volume of air bypassing the core to flow around it.

By reducing the core size and increasing the size of the turbofan it powers, while maintaining the same level of thrust output, the HyTEC concept could lead to reduced fuel consumption and lower carbon emissions.

“HyTEC is an integral part of our RISE program,” said Kathleen Mondino, who helps lead RISE program technologies at GE Aerospace. “GE Aerospace and NASA have a long history of collaboration to advance the latest aviation technologies. The HyTEC program builds on this relationship to help chart the future of more sustainable flight.”

Another piece of the puzzle is hybridization. HyTEC’s hybrid-electric capability means the core will also be augmented by electrical power to further reduce fuel use and carbon emissions.

“This engine will be the first mild hybrid-electric engine, and hopefully, the first production engine for airliners that is hybrid-electric,” Nerone said.