Summary

- Boom Supersonic’s CEO has announced that the company has been conducting combustor rig tests for the Symphony engine.

- The company has been using a 3D printed combustor rig, with the first tests looking at the aerodynamics of the combustor.

- On June 17, Boom Supersonic held a ribbon-cutting ceremony at its Overture Superfactory, where it plans to build 33 of its supersonic aircraft per year.

Blake Scholl, the founder and chief executive officer (CEO) of Boom Supersonic, the company that aims to develop and build its own supersonic jet, has disclosed that the company has begun combustor rig tests of its engine, marketed as the Symphony, using a scale model that was 3D printed in eight weeks. The Symphony will power the Boom Supersonic Overture, a supersonic jet that will fit between 64 and 80 passengers.

3D printed in eight weeks

Scholl disclosed in a thread on X, formerly known as Twitter, that the development of Symphony has been accelerating, with combustor rig tests that have begun this week in Jupiter, Florida, where Florida Turbine Technologies (FTT), one of the companies involved in the development of the engine, was based.

Photo: Boom Supersonic

The CEO highlighted that the combustion test rig was built in just eight weeks, as the company used stereolithography (SLA) 3D printing to build the rig. The rig is full scale and 1/8 section, measuring 4 feet (1.2 meters) in length and 2 ft (0.6 m) in height, according to the founder.

“Test results will help calibrate our digital engineering and allow us to maximize Symphony’s fuel efficiency — so we reduce the cost of supersonic flight, ultimately allowing more people to benefit from high speed travel.”

Related

A Powerplant At Last: Boom Secures Engine Makers For Its Supersonic Overture

The future of the project had long been in question after major engine makers declared no interest.

Combustor aerodynamics

Scholl shared that the first tests focused on combustor aerodynamics, with the CEO adding that nearly 80 pressure sensors measure flow details from the high-pressure compressor, around the fuel nozzles, and through the combustor. Providing context, the CEO noted that at heart, Symphony is a turbofan engine, which was a proven design that has been powering modern commercial aircraft for decades. But Boom Supersonic’s engine was engineered from the ground up with state-of-the-art materials and aerodynamics and was tuned for reliable and economical supersonic flight.

“Jet engines are not quite rocket science (arguably, they are harder, thanks to stringent reliability and safety requirements)—and that’s why we are taking a rapid development approach, quickly turning designs into hardware and conducting real-world tests.”

Photo: Boom Supersonic

The executive teased that Boom Supersonic would unveil more about the Symphony engine at the upcoming Farnborough International Airshow, which will take place between July 22 and July 26 in Farnborough, Hampshire, the United Kingdom. During last year’s Paris Air Show, Boom Supersonic unveiled Aernnova, Leonardo, and Aciturri as three new suppliers for the Overture, its supersonic aircraft.

Related

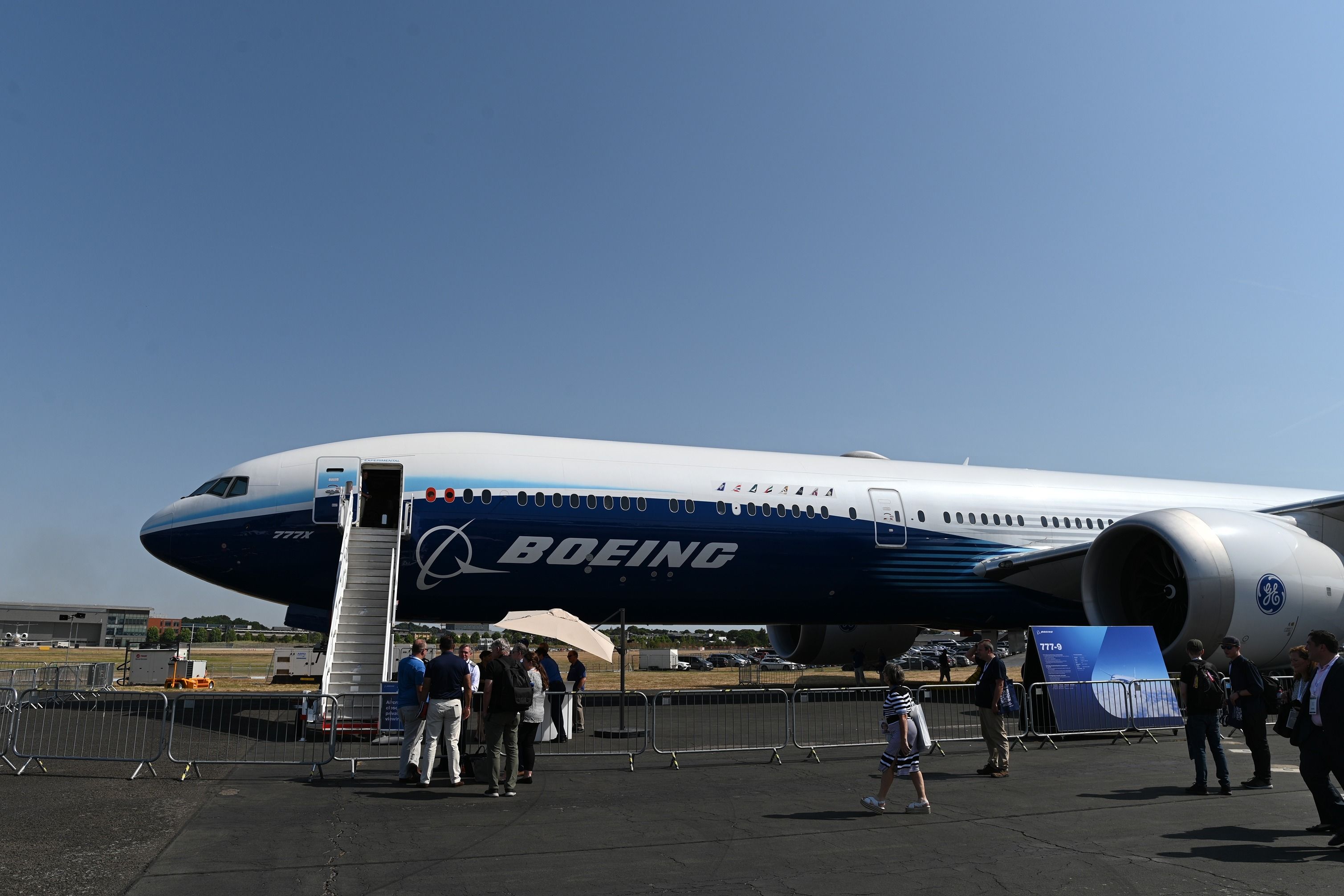

Boeing Will Not Bring 737 MAX Or 777X Test Aircraft To Farnborough Airshow 2024

Instead, Boeing will be represented with a Qatar Airways Boeing 787-9 and a Royal Air Force (RAF) P-8 Poseidon.

Building its Superfactory

The news about the scale-model combustor rig tests came shortly after Boom Supersonic held its ribbon-cutting ceremony at the Overture Superfactory in Greensboro, North Carolina, US, which is located near Piedmont Triad International Airport (GSO) on June 17.

At the time, Scholl remarked that the factory played a part in ensuring that the US remains a leader in aerospace manufacturing in the world, with the executive promising that supersonic travel would transform air travel.

“Hundreds of millions of passengers will fly supersonic on aircraft produced at the Overture Superfactory. This first assembly line has the capacity to produce 33 Overture aircraft per year, valued at more than $6 billion.”

However, while supersonic travel had been a reality when Concorde was still flying with Air France and British Airways colors, the supersonic age experienced its end in 2003, when both airlines retired their supersonic jets. One of the reasons was that supersonic travel was limited to flights over water, with the Federal Aviation Administration (FAA) banning supersonic flights over land due to noise and sonic boom concerns.

Related

Boom Supersonic Receives Special Flight Authorization to Exceed Mach 1

Boom Supersonic now has the legal authority to take its XB-1 prototype past Mach 1, the speed of sound. Read on for details.

Quiet supersonic flight

NASA and Lockheed Martin have been researching how to reduce the noise pollution, including sonic booms, of supersonic flight. The two companies unveiled the X-59 quiet supersonic aircraft in January. At the time, NASA detailed that the experimental aircraft was at the center of NASA’s Quesst mission, focused on providing data to help regulators reconsider rules that have prohibited commercial supersonic flight overland.

“For 50 years, the U.S. and other nations have prohibited such flights because of the disturbance caused by loud, startling sonic booms on the communities below.”

Photo: Jonathan E. Hendry | Simple Flying

The agency added that the X-59 was expected to fly at 1.4 times the speed of sound, or 925 miles per hour (1,488 kilometers per hour). The design, shaping, and technologies used to develop the aircraft will allow the aircraft to achieve these speeds while generating a softer sonic boom.

Related

NASA and Lockheed Martin Unveil X-59 Supersonic Jet

The aircraft will test new technologies to reduce the sonic boom to a dull thud and gather data to support eventual supersonic flights over land.