Summary

- Airbus’ fleet commonality among its family of narrowbody and widebody aircraft has brought several benefits to pilots and airlines.

- The Fly-By-Wire (FBW) technology, shared among Airbus aircraft, has significantly improved aircraft safety and operations efficiency.

- Overall, Airbus’ fleet commonality has revolutionized the aviation industry by streamlining operations, reducing costs, and improving safety.

Airlines prefer to have fleet commonality in terms of aircraft type and manufacturer (aircraft and engine). It is preferred to ensure streamlined operations across the airline network, reduced cost of training of flight crew and aircraft maintenance.

When the first Airbus A340 rolled out on the runway for its maiden flight in 1991, it sort of changed the direction of the aviation industry forever. It was the very first time in history that an aircraft shared a cockpit layout and an operational philosophy with an aircraft with a different mission capability, configuration, and size.

The aircraft in question is the Airbus A320. The cockpit similarity between the A320, A340, and A330 is uncanny. The below image shows the cockpits of the Airbus A320 narrowbody (left) and the Airbus A330 widebody (right).

For an untrained eye, finding the small differences between them would be quite difficult. In this article, we will look at how Airbus made this possible and how it has benefited pilots and airlines.

It all started with the Fly-By-Wire (FBW) technology

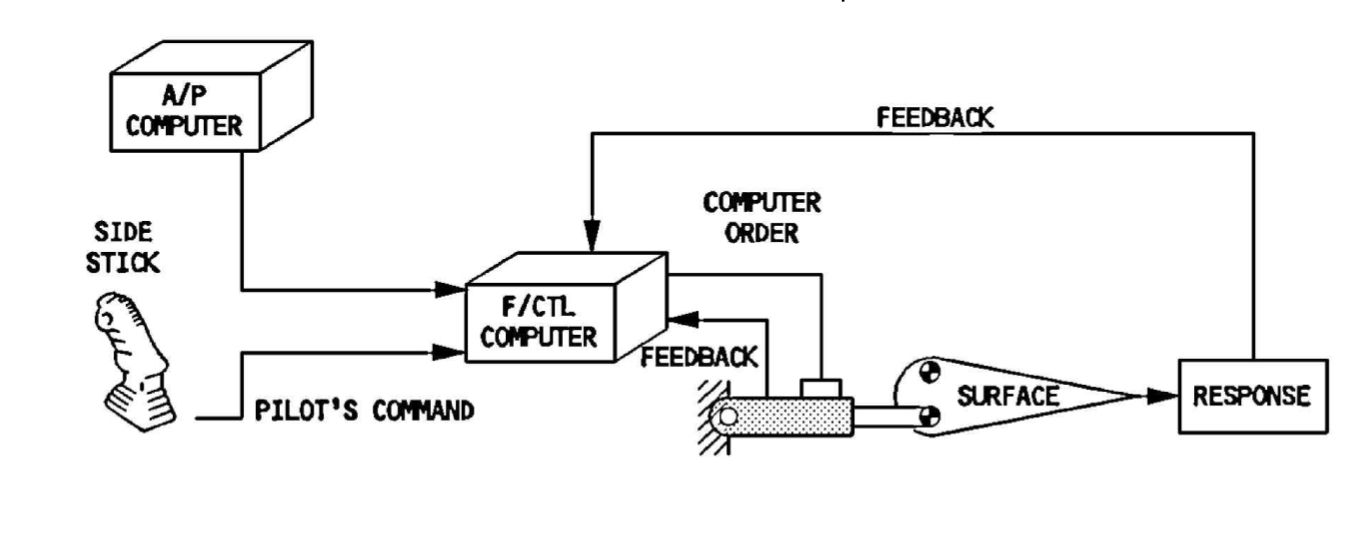

- Flight control systems use computers to process flight control inputs

- It can work for manual or autopilot inputs

- Corresponding electrical signals are sent to control actuators

- Replacing mechanical linkages, pilot inputs do not directly move control surfaces

The A320 is the first civilian aircraft with a digital fly-by-wire system. The fly-by-wire system differs from the conventional flight control system in that it makes controlling aircraft much easier. In the fly-by-wire control system, the pilot control inputs are detected by sensors, and these inputs are then sent to flight control computers which process the data and send it to the hydraulic actuators, which move the control surfaces to make the aircraft behave as per the pilot’s demands.

According to Airbus,

“What is it? We call fly-by-wire the flight control systems which use computers to process the flight control inputs made by the pilot or autopilot, and which send corresponding electrical signals to the flight control surface actuators. This technology replaces direct mechanical linkage.”

Related

A Look At The Fly By Wire Control System

The fly-by-wire system has been a revolution in flight control systems design and is a feature found in many aircraft that are being designed today.

The control computers are governed by a set of written codes which are called control laws. All Airbus aircraft starting from the A320 have similar control laws. For example, the pitch control is a g-load demand, roll control through the side stick gives a roll rate demand, the rudder a side-slip demand etc. So, even when the aircraft is heavier and aerodynamically different, it behaves similarly. There are some small differences even between the A320 and A321, with the latter being a little sluggish to control inputs. But these differences are easily learned.

Image: Airbus

Operational philosophy and ECAM (Electronic Centralized Aircraft Monitoring)

- Weight saving by removing cables, pulleys and rods

- Improved flight safety

- Ease of access

- Enhanced aircraft maneuverability

- Greater situational awareness

All Airbus aircraft have the same philosophy when it comes to operating the plane. The checklists are similar for Airbus fly-by-wire aircraft. And just last year, Airbus released new checklists for all their aircraft, which further harmonizes the checklist similarity across their fleet.

The other operational advantage Airbus offers is the cockpit layout. All Airbus fly-by-wire aircraft have very similar placement of various control levers, push buttons, etc. For instance, if an A320 pilot is put in the seat of an A350, he or she could figure it out in a matter of minutes. Airbus has gone so far to the point that when the pilot adjusts the seat, the side stick position is the same for all of their aircraft. This makes it easier for the pilots to get adjusted to a new type during transition.

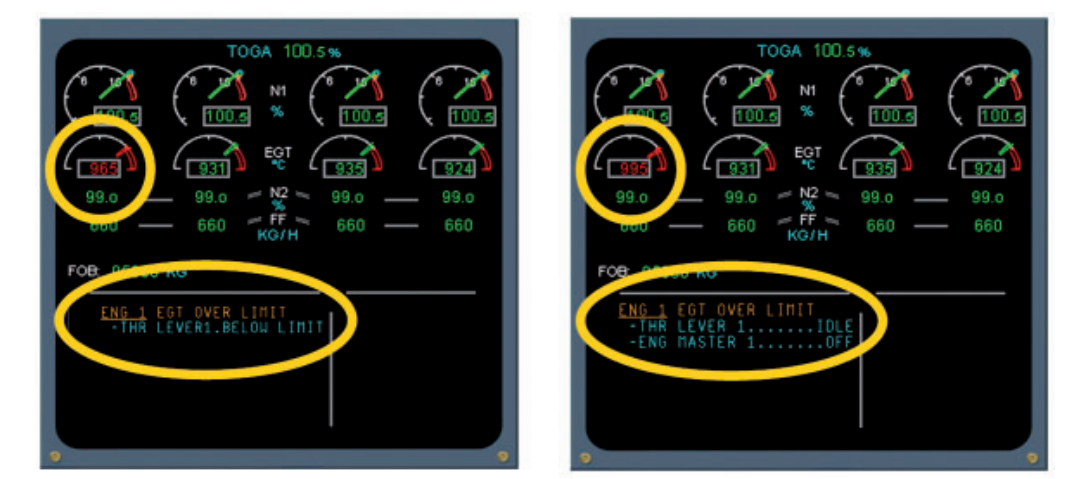

As highlighted by Skybrary, the ECAM (Electronic centralized aircraft monitoring) is the heart of Airbus fly-by-wire. ECAM monitors every single parameter of the aircraft. When a failure happens, the ECAM alerts the pilots with an emergency read-and-do checklist which can be easily followed by the pilots. This makes the handling of emergencies and abnormal conditions the same in all Airbus aircraft. The way things are displayed in the ECAM is also very similar to Airbus aircraft. This again improves the easiness of operation.

Image: Airbus

One other fun feature is the flaps. All Airbus aircraft have the same flap setting. FLAPS 1, FLAPS 2, FLAPS 3, and FLAPS FULL. The degree the flaps are set with these configurations differs from aircraft to aircraft. However, when flying, for the pilot, the flap settings are the same. So, even if you are in an A380 after flying the A320, the callout for flaps remains the same. FLAPS 3 callout A320 is the same as the FLAPS 3 callout in the behemoth A380.

Related

Airbus Shares Plummet Nearly 10% Following Profit Forecast Cut

Airbus has also pushed its monthly delivery target of 75 A320 jets from 2026 to 2027.

What benefits does the commonality offer to pilots and airlines?

The main benefit for pilots is that it makes the transition from one Airbus aircraft to the other much easier. When pilots make the transition from one aircraft type to another type, they are required to undergo a Type Rating course. This is usually a 40-day course where the pilots learn new aircraft systems and procedures and fly the aircraft simulator. To pass the type rating, a skill test must be passed with a type rating examiner at the back of the full motion simulator.

According to Airbus,

“Designated as the fourth-generation aircraft, the planes that have been operated since then have accumulated over 30 years of in-service experience. This represented more than 200 million accumulated flights at the end of 2021 by a fleet of more than 14,500 aircraft in service, which is a strong statistical basis. Fly-by-wire has significantly improved aircraft safety and operations efficiency.”

Once type rated, the pilot is required to undergo line training in the airline where he/she must fly with instructor pilots in normal passenger flights. Each line training flight is assessed until the instructors release the pilot for a line check. The line check is also conducted in a revenue flight with an instructor or an examiner. Once the pilot passes the line check, then only can he/she fly with line pilots. This is the traditional route which is quite expensive and time-consuming for the airline. With the CCQ, pilots can start flying in revenue flights in a short period of time.

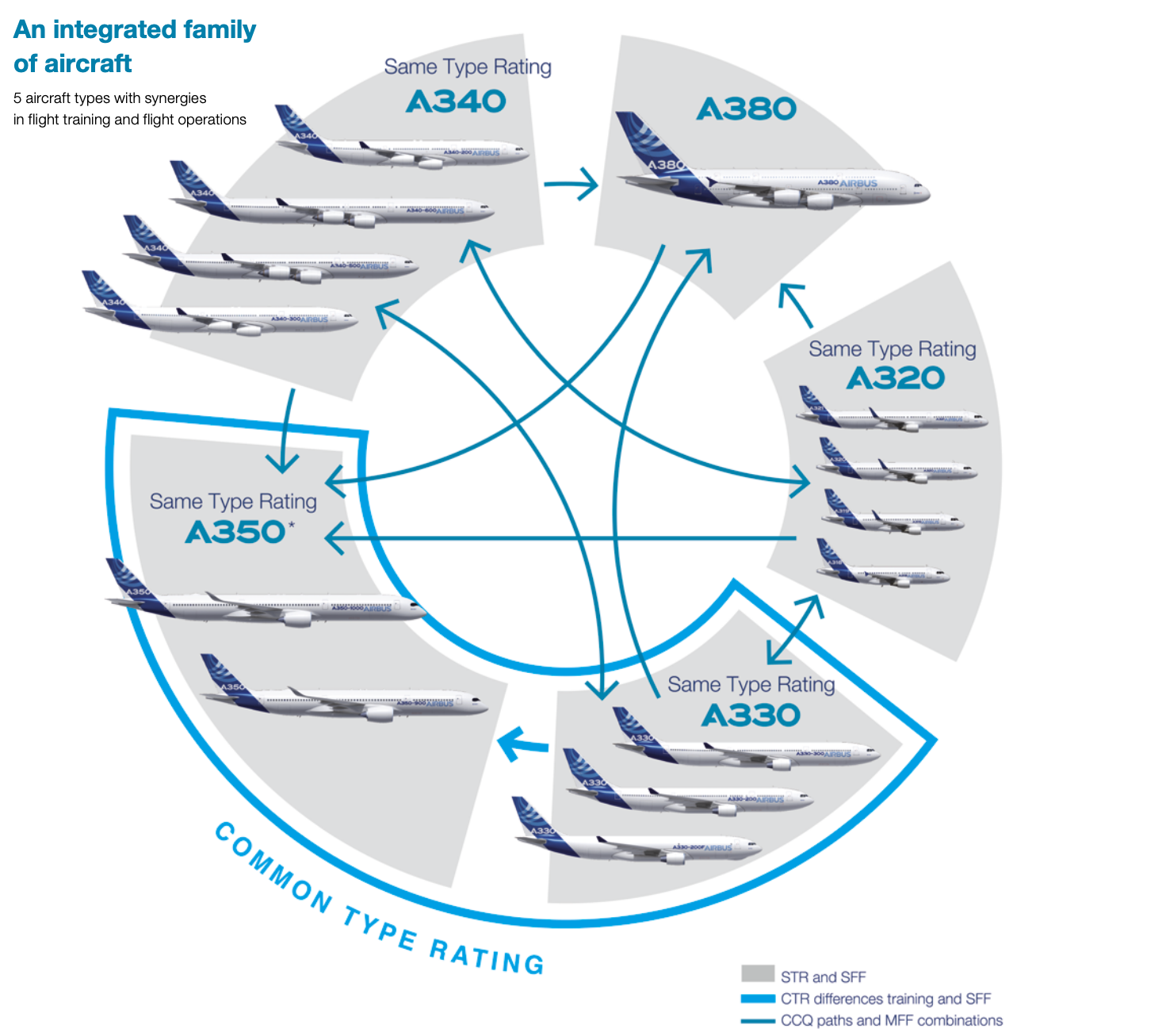

As Airbus aircraft are similar, a full type rating is no longer required when transitioning to another Airbus type. Airbus calls this short conversion course Cross crew qualification, or CCQ for short. In a CCQ program, the pilot only learns the differences between the types. For example, if a pilot is already type-rated on the A320 and wants to get type-rated on the A330, he/she can do a CCQ. And in the course, he/she is only required to learn what is different in the A330 when compared to the A320.

One such system is the much more complex fuel system in the A330. The A320 to A330 CCQ takes about 7 days, compared to the 40 days required for a traditional type rating. The longest Airbus CCQ program is transitioning from the A320 to the A380, which takes about 11 days. This is still a far cry from a typical type rating course. The line training is also shortened for pilots. All of these factors reduce the money spent by the airline to train pilots on newer Airbus aircraft.

Image: Airbus

The most interesting airplanes in the Airbus lineup are the A330 and the A350. They are considered as one single type. When a pilot completes his/her type rating on the A330, he/she also automatically gets the A350 endorsement. But to fly the A350, non-full simulator classroom training is required, just to address the small differences between the aircraft.

The CCQ leads to MFF (Mixed fleet flying)

Mixed fleet flying (MFF) allows pilots to fly two separate Airbus types together on an airline. For instance, many airlines have pilots who fly the A320 and the A330 (sometimes including the A350) together. This is called MFF. The benefit of MFF for the airline is that it allows them to use the same pool of pilots in both short to medium and long-haul operations. This greatly cuts costs as the requirement to maintain a separate set of pilots for two different operations is no longer there.

This also makes operations a lot safer. Long-haul pilots have comparatively less take-offs and landings when compared to short-to medium-haul pilots. This degrades pilot skill. With MFF, pilots get the opportunity to enjoy both long-haul and short to medium-haul, which keeps them sharp.

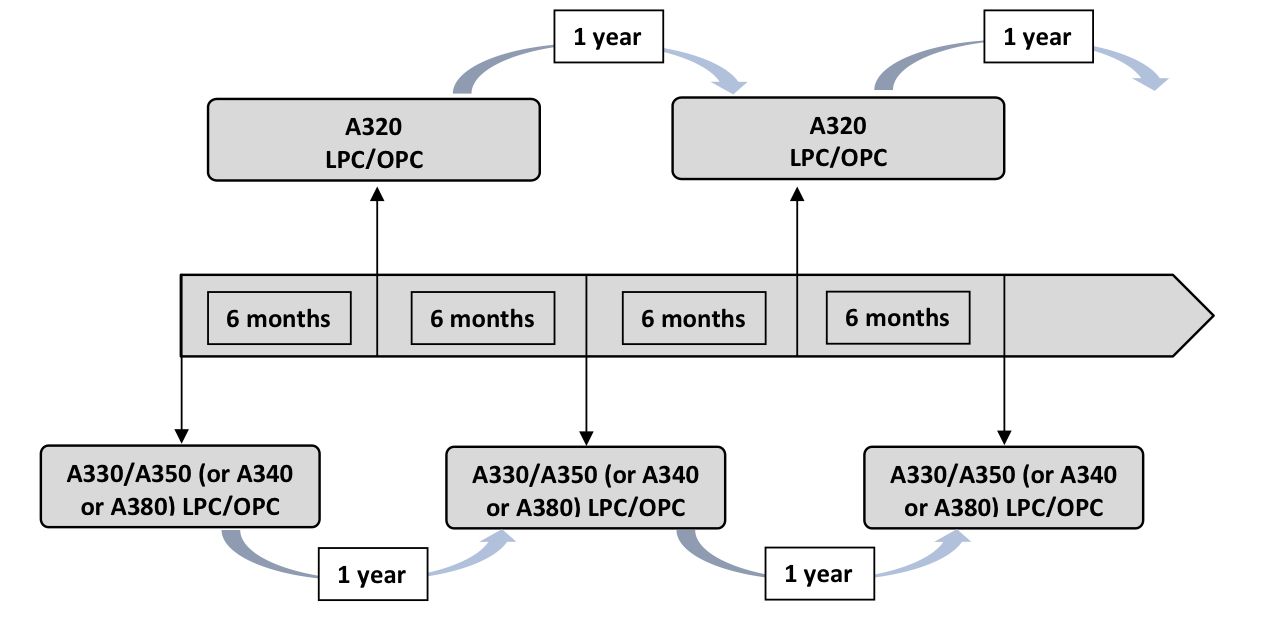

Photo: Airbus

One question that might be in your mind is how pilots maintain their proficiency when flying MFF, as pilots undergo 6-month simulator checks and an annual line check, and, they need to maintain their aircraft. For the simulator checks, the types can alternate. For instance, if a pilot is rated on the A320 and CCQed on the A330 and is flying MFF, his first 6-month check can be done on the A320 and the following 6-month check can be done on the A330. The line checks are similar, but the type gets reversed every year as the check is only done annually.

Image: Airbus

For recency requirements, the regulations state that a pilot must perform three take-offs and landings on the type within 90 days. When flying MFF, the regulators say that a pilot can do the three take-offs and landings in either aircraft within 90 days as long as one take-off and one landing in each type is performed every 45 days.

Related

5 Reasons Why This Year Was So Successful For The Airbus A320 Family

Will Airbus continue running away with the competition in the narrowbody market?

What are your thoughts on Airbus’ type commonality among its family of narrowbody and widebody aircraft? Have you peeked through an Airbus cockpit? Share your experiences in the comments section.