Summary

- Speed tape is a durable, adhesive material designed to promote aircraft safety and withstand extreme environments.

- It is used for temporary, minor repairs to specific airplane components.

- Speed tape solves errors that do not affect an aircraft’s structure but can impact airflow and aerodynamic performance.

Have you ever seen taped parts of an aircraft’s wing or tail surfaces? Have you ever wondered what the purpose is? Is it a quick-fix solution? Is it safe?

Some believe duct tape can fix everything, but they would be mistaken. Indeed, it has various good uses inside and outside the home, but simple duct tape would not last long against the temperatures, forces, and elements that aircraft of all types experience. So, the industry has found another solution, called speed tape.

Related

A Look At The Various Aircraft Maintenance Tasks And Checks

Keeping the aircraft maintained and airworthy is the operator’s primary responsibility.

What is it, and what exactly is it made to tolerate?

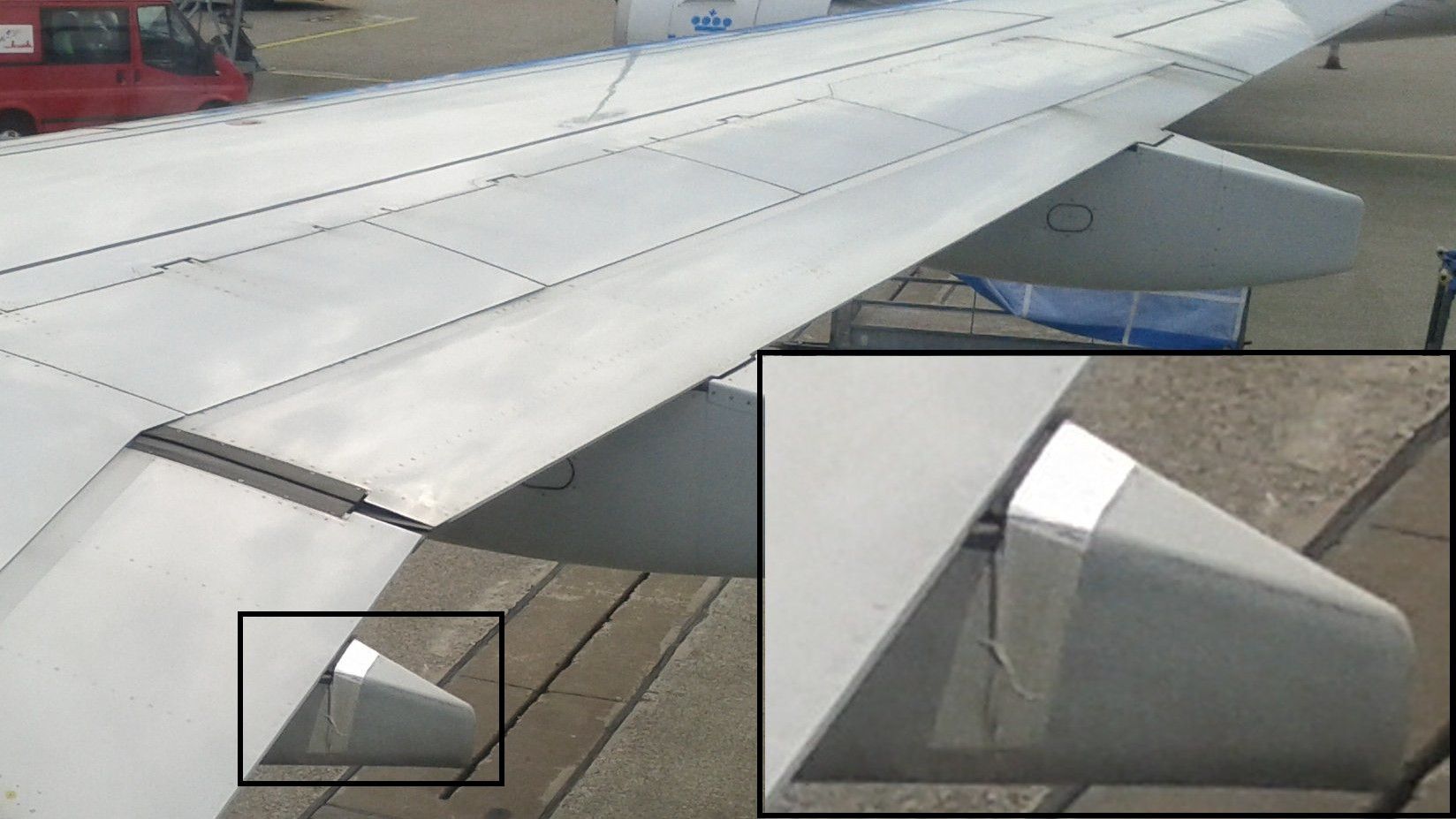

As this material is made primarily from aluminum, which is silverish-grayish in color, one could be forgiven for pondering why it appears duct tape is helping to patch something on an aircraft wing. After all, there are plenty of photos on social media joking about low-cost carriers using duct tape to keep the airframe together. However, people posting this content should know that speed tape is helpful for any operator and that its properties are far beyond what duct tape can do.

According to The Sydney Morning Herald, speed tape is specifically designed to withstand temperatures ranging from -65 to 300 Fahrenheit (-54 to 149 Celsius), wind speeds of around 600 MPH (966 KPH), water, flames, ultraviolet rays, and a myriad of environmental changes. This pressure-sensitive tape is as adhesive as it is durable, though it’s likely not holding together two critical aircraft pieces.

Though it is mainly a solution until the plane undergoes more extensive maintenance than just where the tape is placed, there are strict rules governing how carriers can apply it. According to John Nance, a veteran pilot and safety consultant, as reported by The Sydney Morning Herald,

“There’s never going to be a piece of garden-variety duct tape used on an airplane. So if you’re looking at it, it’s called speed tape and it’s very, very specifically designed to do whatever it is they’re trying to make it do.”

Related

Useful Tools: 5 Key Pieces Of Equipment For Aircraft Maintenance Teams

Among hundreds of tools and equipment, here is our list of essentials.

An airline pilot, Patrick Smith, describes that the speed tape is used on on superficial components and it is not the critical issues that the tape fixes. According to Patrick Smith, as recorded by CN Traveler,

“What you’re actually seeing is a heavy-duty aluminum bonding tape known as ‘speed tape’. “It’s a temporary fix and it’s used only on superficial or noncritical components, until more substantive repairs are made later on.”

A spokesperson for the Federal Aviation Administration (FAA), the United States’ regulatory authority, said this material can be used for “temporary, minor repairs to nonstructural aircraft components.” The same source explains that, in the US, airlines outline how and when they plan to use the tape, and the FAA must approve this document.

In the early 2000s, the FAA fined United Airlines $805,000 for operating nearly 200 flights with speed tape applied to holes larger than permitted and that were too close to the wing spoilers.

So why would a carrier want to use it?

All said, speed tape is an excellent solution for minor issues or cosmetic errors that would not otherwise cause a critical failure during flight. Perhaps it’s just a case of peeling paint that doesn’t affect the overall aircraft structure, or maybe there’s a minor bump, scratch, or hole that doesn’t force the plane to be stuck on the ground. But such things can interfere with airflow and aerodynamic performance.

Ideally, aircraft surfaces are as flat and smooth as possible to facilitate optimal conditions for flight. Airflow over a pair of wings is critical to achieving flight, and while minor cosmetic damage won’t hinder an aircraft from taking off and cruising, it can still cause minor imperfections in how the air moves.

Speed tape can lessen or mitigate these issues by making the surface flat again, so a maintenance worker can apply some of the adhesive material during routine inspections before a flight, say during a turnaround.

Photo: Ranglen | Shutterstock

Once the aircraft goes into maintenance as it usually would, the airline will find a more permanent solution for whatever made them want to apply speed tape in the first place. Given the material’s properties, it has uses outside of aviation, such as on race cars, where speed, aerodynamics, and extreme elements are also featured.

The thing to note is that the pressure-sensitive tape costs hundreds of dollars and can withstand aircraft cruise speeds. It is approved by regulatory authorities globally to be used on non-critical, mostly cosmetic, issues until a substantial fix is performed.

Related

What Are The Typical Scopes & Costs Of Engine Maintenance Work?

Comprehensive maintenance of jet engines may cost operators several million dollars.