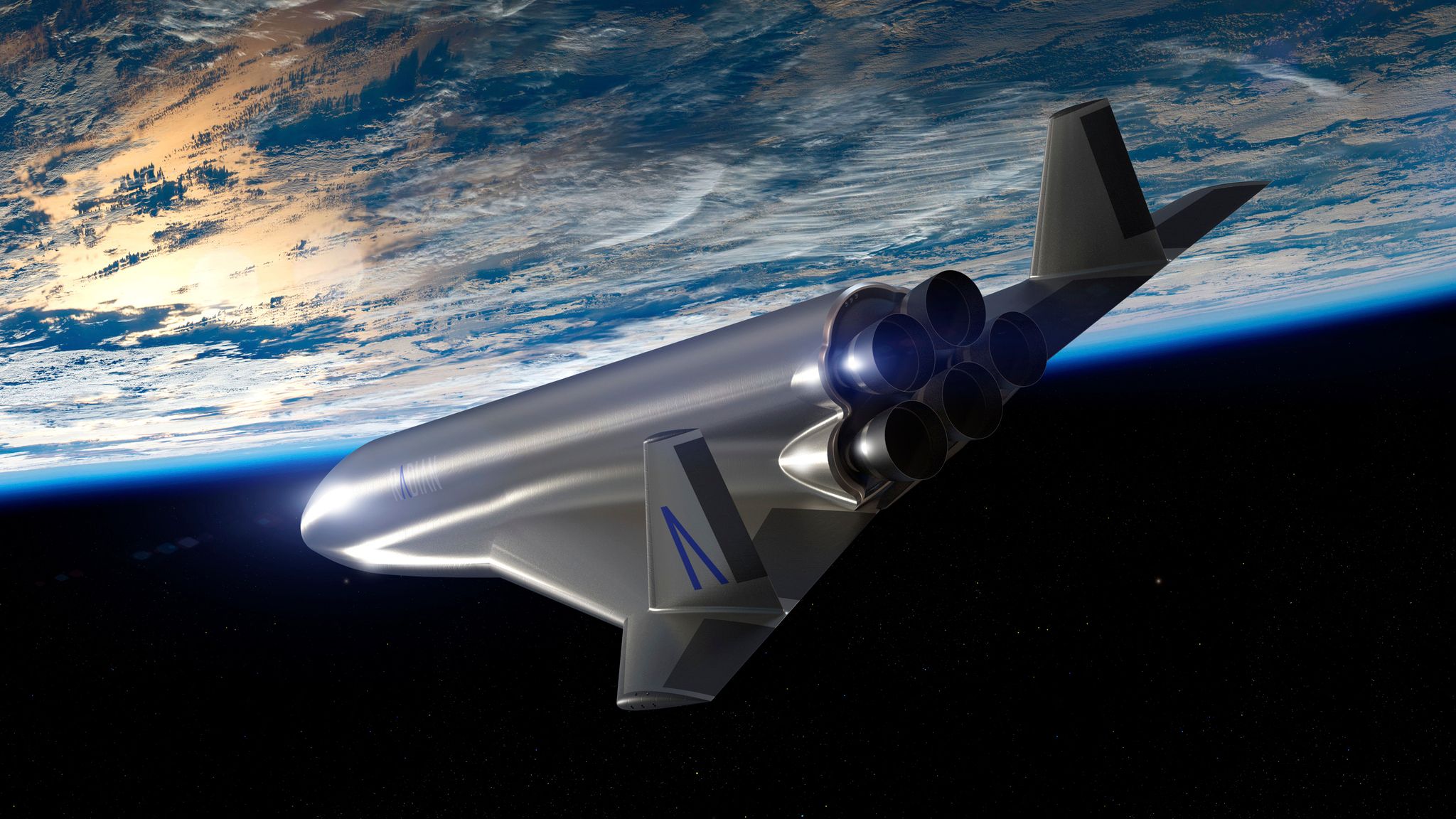

On September 25, 2024, Seattle, Washington-based Radian Aerospace issued a statement saying that it had completed the first round of ground taxi tests with its single-stage-to-orbit (SSTO) space plane, the Radian One, billed as the world’s first fully reusable space plane. The tests, which took place in Abu Dhabi, were designed to test the spacecraft’s low-speed takeoff and landing characteristics.

Photo: Radian Aerospace

During the ground tests, the vehicle performed a series of maneuvers and hops to collect critical data from its integrated telemetry systems. The successful completion of the tests means that the American startup is now one step closer to building a reusable spaceship that can launch vertically like a rocket and then land on a runway like an airplane.

How the Radian space plane came to be

During the 1990s, the National Aeronautics and Space Administration (NASA) worked on a cost-effective, usable space plane to replace expensive one-off rockets. Called the “X-33,” the experimental vehicle was based on a concept NASA called “single stage to orbit” (SSTO). The plan was for the SSTO to replace conventional rockets that jettisoned stages during flight to lower the weight of the spacecraft. NASA calculated that by using the SSTO spaceship, the cost of sending a pound of payload into orbit would be reduced from $10,000 to $1,000.

Photo: Radian Aerospace

After having worked on similar projects that failed to materialize, the project was canceled in 2001 due to technical difficulties. According to Livingston Holder, a former United States Air Force (USAF) astronaut and program manager of the X-33 program, they were on the brink of making a breakthrough when the program was canceled. Over the next decade and a half, Holder was convinced he could make an SSTO spacecraft and partnered with Richard Humphrey, Jeff Feige, and Curtis Gifford to find Radian Aerospace.

New technologies are turning a dream into a reality

During an interview with CNN, Holder said:

“Things have changed dramatically since the X-33 — we’ve got composite materials that are lighter, tougher, and can take a larger thermal range than we had back then. And propulsion is better than anything we had, in terms of how efficiently it burns propellant and how much the systems weigh.”

Since its founding in 2016, Radian Aerospace has successfully built the PFVOL using revolutionary composites and the tools needed to analyze real-time data using integrated flight sensors. After the successful ground tests in Abu Dhabi, Radian Aerospace plans to use a longer runway in the region to allow for sustained flights at higher speeds. The lessons learned from the tests can then be integrated into the Radian One spacecraft.

Related

Should Space Exploration Remain A Priority?

After a period of somewhat quietness, space agencies across the globe are ramping up their exploration programs. With the world going through several short-term crises, some speculate that space exploration shouldn’t be such a priority when it comes to the use of resources and expenditure. What are your thoughts? Let us know what you think below!

A rocket needs to reach a high velocity to escape Earth’s gravity

According to Massachusetts Institute of Technology (MIT) astronautics professor and former NASA astronaut Jeffrey Hoffman, to be able to send a vehicle into space, the rocket firing it needs to travel at around 17,500 miles per hour. After having successfully completed four Space Shuttle missions, Hoffman knows what it takes to escape the Earth’s gravity and says that the weight of the rocket’s fuel takes up 95% of the rocket and payload weight to reach the velocity needed.

For this reason, as the rocket burns fuel and gains altitude, stages are jettisoned to make the vehicle lighter. While it has long been a dream to enter orbit with a single stage, the vehicle’s total mass cannot exceed more than 5% of its total weight, and so far, engineers have not possessed the knowledge to build such a vehicle.

Photo: Radian Aerospace

The older Apollo Saturn V rockets that took man to the Moon used three stages, while newer rockets like the SpaceX Falcon 9 only use two. Traditionally, the spent stages of the rocket fall back to Earth and land somewhere in the sea. Still, SpaceX has developed a system where the rocket boosters autonomously return and land to be used again, a brilliant innovation that reduces costs. Using a single-stage reusable vehicle like the one Radian Aerospace is working on would cut the costs even further.

Radian is convinced that they can build a reusable SSTO vehicle

They say that the reason it can be done is down to three key technologies, which are:

- Sled launch system: A sled launch system utilizes a ground-based launch assist to get the vehicle airborne, allowing it to have a full tank of fuel still. A ground-based launch assist uses a rail or maglev track to propel the vehicle to a specified velocity. This type of launch could be used repeatedly, dramatically reducing the cost of space flight.

- The landing gear: The landing gear designed for Radian One is not for taking off but only for landing, making the vehicle considerably lighter.

- The wings: Unlike traditional rockets, adding wings reduces the required thrust and allows the vehicle to utilize life while flying toward orbit.

The closest analogy to Radian One is that one in orbit and returning to Earth will be very similar to the Space Shuttle. Radian One can perform the same missions that the Space Shuttle did but with a faster turnaround time and a greatly reduced cost. Radian says that the Radian One can carry between two and five astronauts and have a 48-hour turnaround time between missions.

Because the vehicle uses a more robust composite on its exterior surface, the company estimates that each craft can be reused up to 100 times. The big question is not whether a single-stage-to-orbit vehicle is possible, but whether it can do so at a competitive cost with other launch systems like the one used by SpaceX.