The official report into how a Qantas Airbus A380 flew for almost 300 hours and 34 flights with a tool lodged in one of its four engines has been published by the Australian Transport Safety Board (ATSB). The report has made recommendations to be followed by the Australian airline so that any future such events are avoided.

On December 6, 2023, one of Qantas’ 10-strong fleet of Airbus A380-842s arrived at Los Angeles International Airport (LAX) at the end of a routine scheduled passenger flight from Sydney (SYD). Engineers from the airline began a turnaround maintenance check on the aircraft (registered VH-OQI) while on the ground at LAX before its return flight to Sydney which was completed without incident.

The aircraft concerned then flew for 294 hours and completed 34 sectors (17 round-trip flights) before its next scheduled maintenance check which was also carried out while the aircraft was on the ground in Los Angeles on January 1, 2024, almost a month after its previous check.

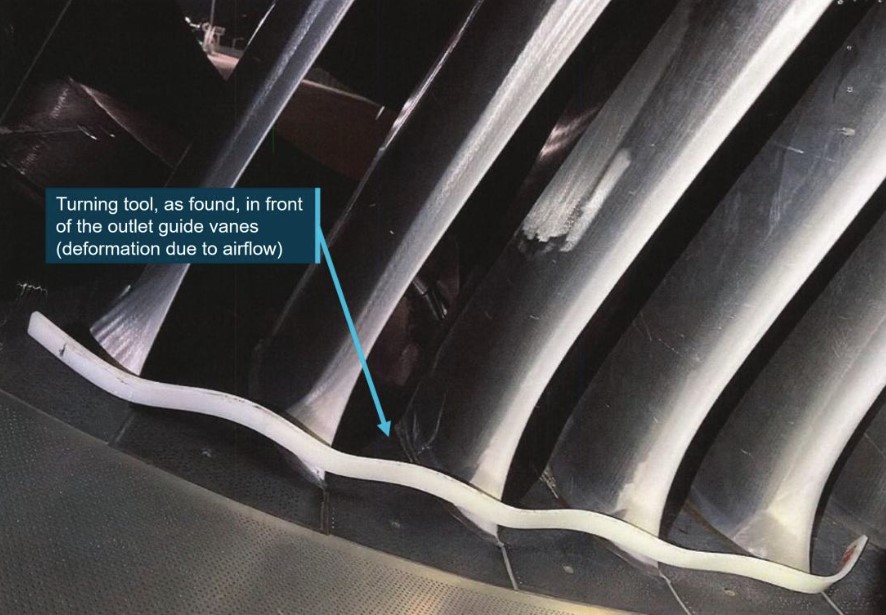

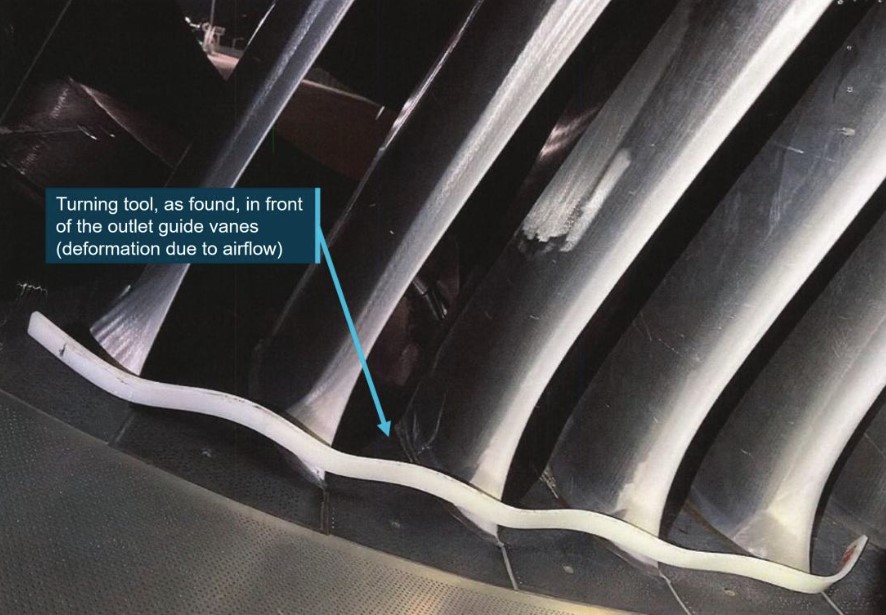

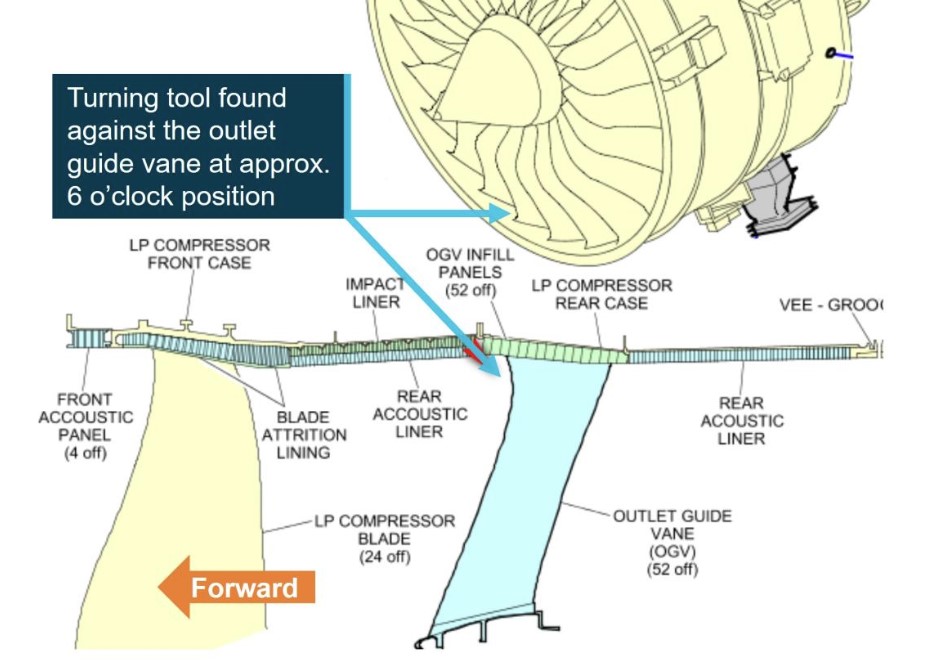

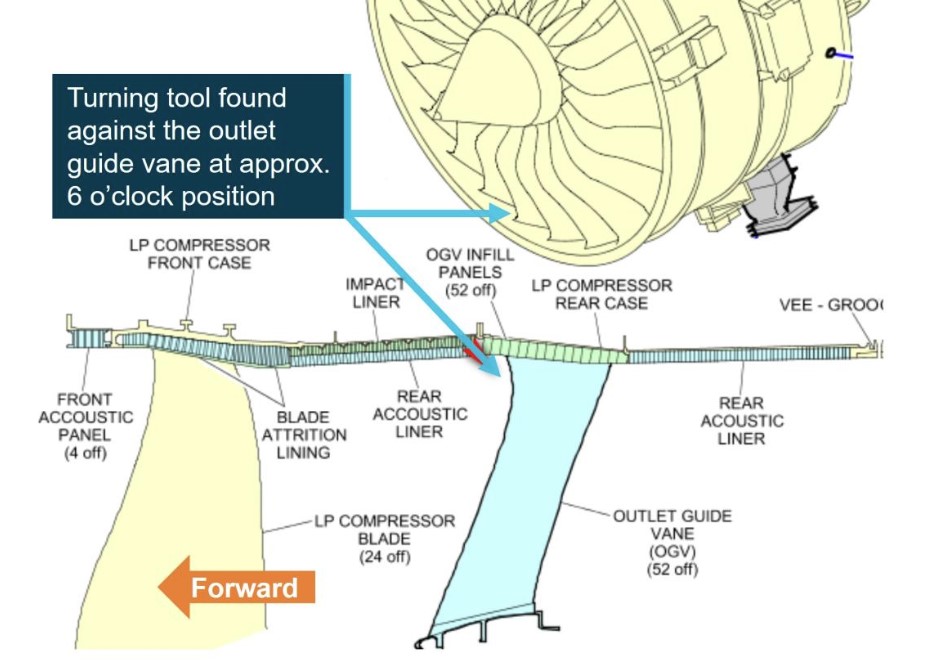

However, upon inspection of the aircraft’s four Rolls-Royce engines, an engineer discovered a 1.25m-long (4 ft) nylon tool wedged against the low-pressure outlet guide vanes in one of the engines. These vanes together from the fan visible from looking at the engine from the front and are a key component of jet turbine engines. The tool is of a type used to turn an engine compressor during borescope inspections, where a detailed examination of engine components is carried out.

Upon review of the aircraft’s maintenance records, the ATSB concluded that the tool had been left in the engine during its previous check in Los Angeles, some 26 days before it was finally discovered. The investigators also discovered that the tool had gone undetected during a shorter maintenance check performed on the aircraft at the end of a three-day maintenance period in December 2023. Nor had it been noticed by crews during their pre-flight external inspection checks before each of the 34 flights.

The ATSB reported that while the tool itself was discovered to have suffered damage and was “deformed” due to its location within the engine and “by high energy airflow”, miraculously, it had not caused any damage to any components of the engine itself.

What has the ATSB said?

“The ATSB investigation found that maintenance engineers did not notice the tool had been left in the engine’s low-pressure compressor case when conducting checks for foreign objects at the completion of the borescope inspection task,” ATSB Chief Commissioner Angus Mitchell said.

“Further, maintenance engineers did not commence the lost tool procedure once the tool had been identified as missing, and the certifying engineer released the aircraft for service with the tool unaccounted for,” he added.

The ATSB investigators’ report states that the turning tool had been left inside the engine inlet by an engineer at Los Angeles who believed it would be needed later in the maintenance. However, subsequent engineers did not notice it and, despite a missing tool report being filed at the time (a mandatory requirement in the event a tool goes missing), it was not found until the engine was inspected as part of scheduled maintenance in Los Angeles almost a month later.

“Foreign object debris and damage can pose a significant threat to the safe operation of aircraft, which is why regulations, procedures, and training are in place to limit the risk of foreign object damage, especially from introduced objects during maintenance. Correctly applying tool control is fundamental to mitigating against any human errors that may arise,” the ATSB report concludes.

The report goes on to state that following the discovery, Qantas Engineering management briefed all staff on the importance of ensuring tools are returned and actioned by store personnel. The carrier also launched an internal investigation that led to a new safety directive being implemented regarding the importance of complying with tool control requirements.

In response to the report’s findings, a statement issued by the airline said that the turning tool, a piece of flexible plastic, had no effect on the engine’s operations and that it had cooperated fully throughout the ATSB investigation.

“We take this extremely seriously and while there was no damage sustained to the engine, it is critical that the correct lost tool processes are followed,” a spokesperson said. “Since this event, we issued an internal safety directive reminding our engineers and tool store team members to adhere to these processes to ensure this doesn’t happen again.”