Aurora Flight Sciences is an aviation and aeronautics research subsidiary of Boeing. It is focused on special-purpose unmanned aerial vehicles (UAVs). On August 21st, the company announced plans to expand its manufacturing facility in Columbus, Mississippi.

Expansion plans

Aurora Flight Sciences Colombus’s manufacturing facility is located near the Golden Triangle Regional Airport. The facility specializes in manufacturing advanced composite components and assemblies for military and commercial aircraft.

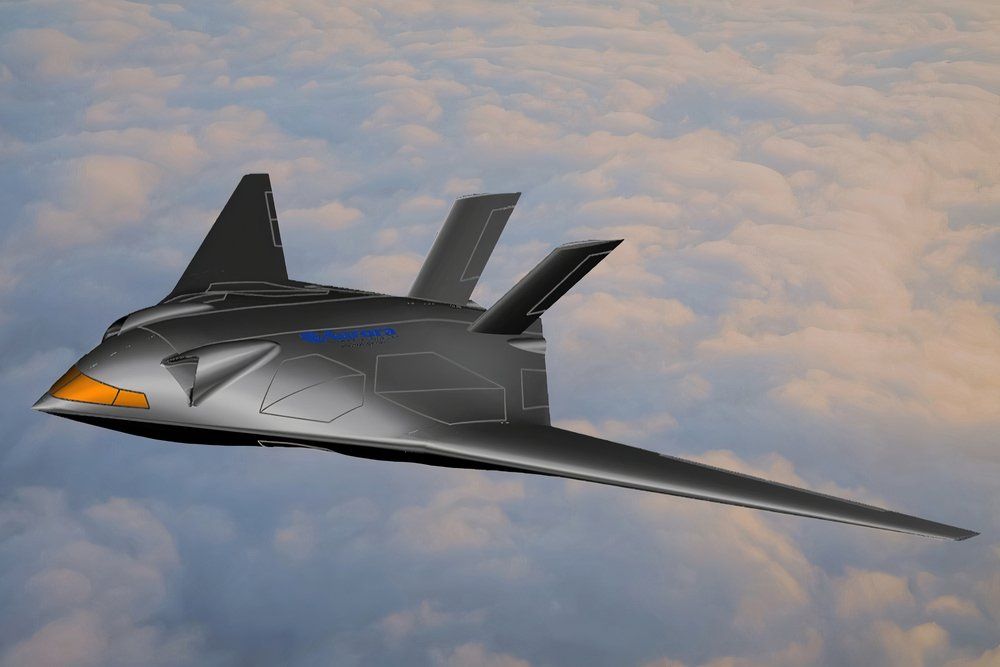

Graphic: Aurora Flight Sciences

According to Aurora’s statement, the expansion project will increase the facility by 50,000 square feet. In addition, another 40,000 square feet of existing space will be renovated, and new automation, robotics, and non-destructive inspection equipment will be introduced to support the company’s growing aerosystems business.

The expansion and renovation will be conducted in phases. The project is estimated to take two years to complete and will be completed in the latter half of 2026.

Luke Colville, Aurora’s vice president of manufacturing, had this to say about the expansion:

“We’re proud to bring this investment to the Columbus, Mississippi community. We are excited to welcome new programs to the facility and are honored that current customers are choosing to grow their business with us. This success is driven by the hard work and dedication of Aurora’s team members here in Columbus. We are thankful for our incredible employees and for the continued support of local organizations such as the Mississippi Development Authority and Golden Triangle Development LINK.”

The company moved into this facility in 2007. It was initially a 21,000-square-foot space, but it has since been expanded to 120,000 square feet to house its advanced manufacturing equipment and other technologies, such as automated fiber placement.

The physical space isn’t the only thing getting bigger at Aurora; the team is also getting bigger. The company currently has 100 full-time permanent employees and plans to add another 60 by the end of next year.

The space will be utilized to support the increased production of composites for executive jet aircraft and to manufacture the composite skins of the Boeing MQ-25TM Stingray UAVs. Lastly, it will also be used to produce parts for the X-66 sustainable flight demonstrator, a joint program between Boeing and the National Aeronautics and Space Administration (NASA).

About Aurora Flight Sciences

Aurora Flight Sciences was founded in 1989 and has produced over 35 aircraft, including the GoldenEye and Orion UAVs. The company has also participated in other projects, including collaborations with the Defense Advanced Research Projects Agency (DARPA), NASA, and the US Air Force (USAF).

Graphic: Aurora Flight Sciences

Boeing acquired the company in October 2017 and has utilized its expertise for its military and commercial aviation projects.

It has five main facilities, including the one in Colombus, Mississippi. They are:

- Manassas, Virginia – Headquarters

- Cambridge, Massachusetts – Aerospace & Autonomy Center and Lab

- Bridgeport, Virginia – Advancement Manufacturing Center

- Lucerne, Switzerland – Aurora Swiss Aerospace

The company is involved in many novel projects. One noteworthy project is the CRANE X-65 (Control of Revolutionary Aircraft with Novel Effectors). Aurora is building and designing this experimental aircraft for DARPA. The aircraft will use active flow control for flight controls at tactical speeds and performance enhancement.

Another project with commercial applications is the EPFD Program (Electrified Powertrain Flight Demonstration), which was developed in collaboration with GE Aviation. The company is working to modify a SAAD 340B turboprop aircraft to fly with a hybrid-electric powertrain.

Boeing

- Stock Code

-

BA

- Business Type

-

Planemaker

- Date Founded

-

July 15, 1916

- Headquarters Location

-

Chicago, USA