Summary

- The Airbus A350 operates the longest commercial flight in the world, flying nearly 9,000 nautical miles.

- Airbus is developing an Ultra-Long-Range version of the A350-1000 for Qantas’ Project Sunrise.

- The A350’s structure consists of over 50% advanced lightweight materials, including Carbon Fiber Reinforced Plastic.

The Airbus A350 is undoubtedly the most technologically advanced commercial aircraft in active service today, and this was a feat achieved by Airbus when the aircraft type entered commercial service about a decade ago. The aircraft has since proved to be exceptionally popular, with airlines from around the world ordering this next-generation, clean-sheet aircraft, which will serve the carriers’ long-haul operations for the years to come.

The following list looks into five unique features of this engineering marvel that make it stand out.

1

The long-range leader

Flying nearly 9,000 nautical miles, the A350 operates the longest commercial flight in the world.

The

Airbus A350

aircraft family is well known for offering the A350-900 aircraft and the larger A350-1000 aircraft, which are the two types of the A350 utilized among airlines today. However,

Airbus

has previously developed a small sub-fleet of the A350-900s for

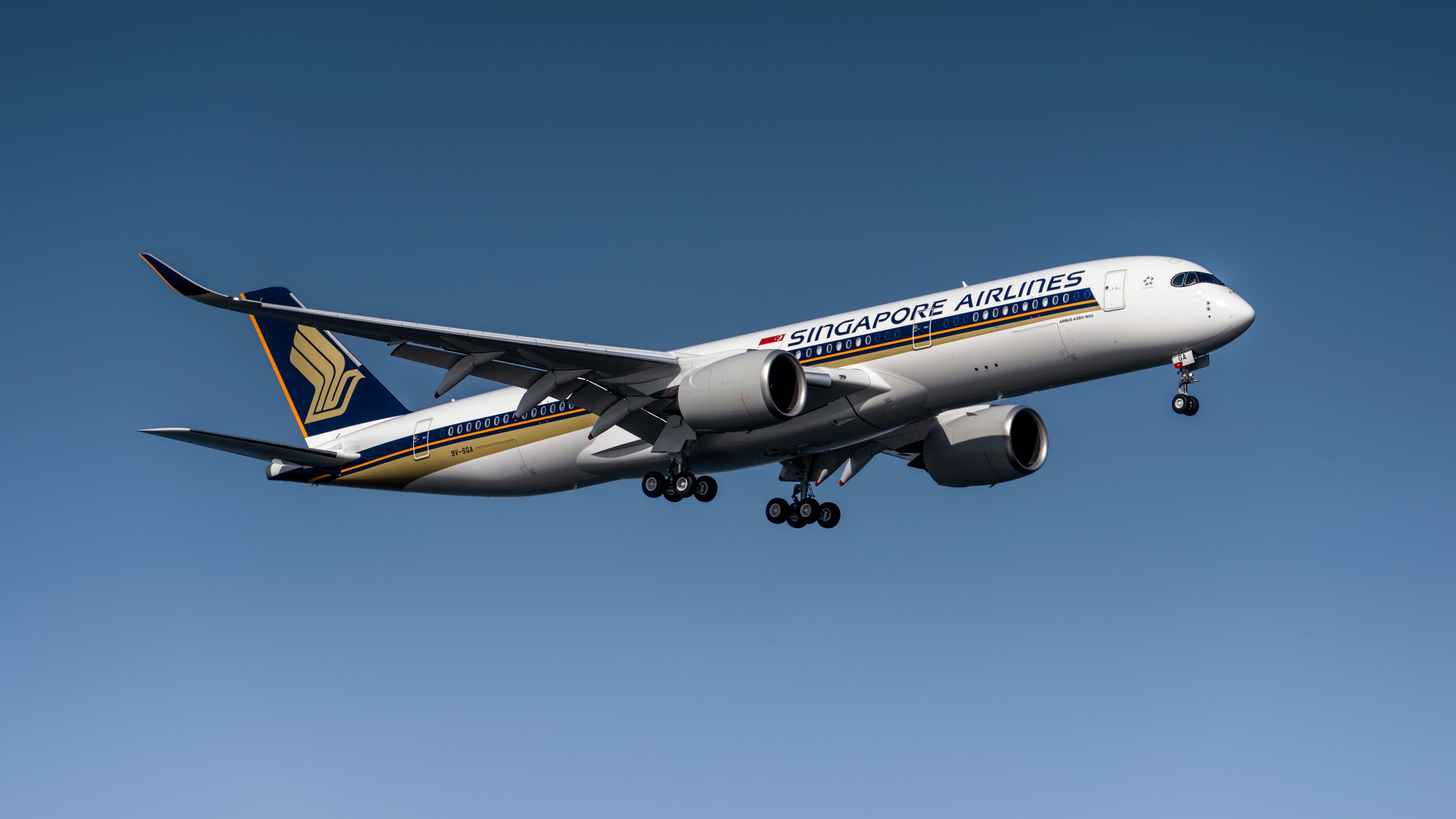

![]() Singapore Airlines

Singapore Airlines

, known as the A350-900ULR (Ultra Long Range), for the carrier to provide non-stop services to its US destinations such as Newark Liberty International Airport (EWR).

Photo: Singapore Airlines

In fact, the Singapore Airlines service connecting Singapore Changi Airport (SIN) and Newark (EWR) is the longest commercial flight in the world, with a flight time of nearly 19 hours and a distance of 9,000 nautical miles (16,700km). Comparing the data of all three variants reveals the range capability.

|

Aircraft |

A350-900 |

A350-900ULR |

A350-1000 |

|---|---|---|---|

|

Range |

8,300 nm |

9,700 nm |

8,900 nm |

The A350-900ULR can fly non-stop for over 20 hours even with a Maximum Take-Off Weight (MTOW) of 280 tonnes.

2

Planning to fly further

While the A350 has the longest range of any commercial aircraft, it will soon increase with Qantas’ Project Sunrise.

While the A350-900ULR has the longest range capabilities of any commercial aircraft, Airbus is working on another variant of the A350, which will be able to fly even longer and further. The aircraft in question is an Ultra Long Range version of the existing A350-1000, which the European manufacturer is currently developing for the Australian carrier

Qantas

.

The carrier finalized its decision on the A350-1000 in 2022, and Qantas intends to use it for direct services from Sydney, Australia, to London Heathrow and other European destinations.

Photo: Qantas

These aircraft will be able to fly nonstop from Western Australia to Europe by utilizing a lighter cabin configuration and an additional fuel tank fitted by Airbus, and upon entering commercial service, Qantas’ Project Sunrise flights will be the longest in the world.

|

Cabin |

First Class |

Business Class |

Premium Economy |

Economy |

Total Seats |

|---|---|---|---|---|---|

|

Capacity |

6 |

52 |

40 |

140 |

238* |

|

Configuration |

1-1-1 |

1-2-1 |

2-4-2 |

3-3-3 |

*These aircraft will feature the lowest number of seats compared to any other operator of the A350-1000.

Considering the long distances the aircraft will be flown, using a lighter configuration enables Qantas to provide more space for passengers, ensuring inflight comfort. The airline will also offer an inflight “Wellbeing Zone,” where passengers can have snacks and drinks or even just stretch.

3

Advanced materials

More than 50% of the aircraft structure is made out of advanced lightweight materials, which improve efficiency while maintaining integrity.

With each generation of new aircraft, the materials used to build various parts of the aircraft have evolved to make the airplanes lighter, which in turn makes them more efficient. With the Airbus A350 being a clean-sheet design, Airbus was able to utilize 53% composite materials.

Photo: Tom Boon | Simple Flying

The material used is known as Carbon Fiber Reinforced Plastic (CFRP), and by utilizing this, the aircraft weight can be reduced while the structure still offers a better strength-to-weight ratio than the conventional aluminum alloys used in making older-generation aircraft. Additionally, this material is less prone to surface degradation or fatigue.

|

Aircraft |

Airbus A380 |

Boeing 787 |

Airbus A350 |

|---|---|---|---|

|

CFRP% used |

16%* |

50% |

53% |

*Data from Composites World.

Among the remaining 47% of materials used in making the A350, 14% of the aircraft structure is made from Titanium, which is another material with a great strength-to-weight ratio.

4

Powered by efficiency

The Trent XWB engine powering the A350 is the world’s most efficient engine currently in commercial aviation service.

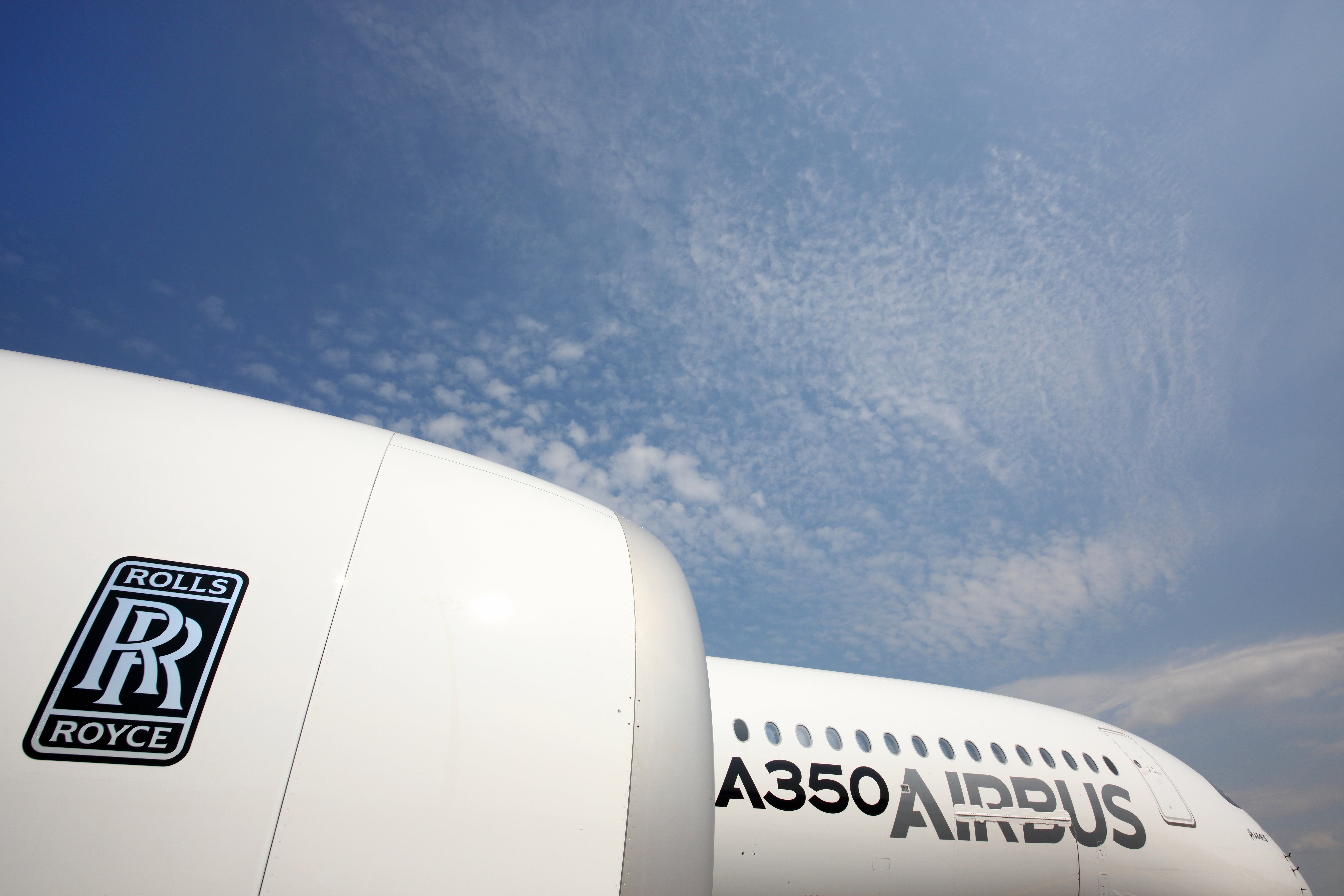

Developed by

Rolls-Royce

, specifically for the A350, the Trent XWB engines are the most efficient engines to power a widebody aircraft and have been optimized to deliver 25% reduced fuel burn and carbon emissions. Just like the aircraft it powers, the engines proved to be exceptionally popular among A350 customers.

Photo: Fasttailwind | Shutterstock

There are two variants of the engine type: the Trent XWB-84 powers the A350-900s, and the Trent XWB-97 powers the A350-1000 (which will also power the A350-F in the future).

|

Engine |

Trent XWB-84 |

Trent XWB-97 |

|---|---|---|

|

Aircraft |

A350-900 |

A350-1000/A350F |

|

Thrust |

84,000lb |

97,000lb |

Rolls-Royce is currently working on upgrades for the XWB-84s, and they are expected to be deployed in 2025, which would boost the engines’ performance.

5

Quick to vacate

The Brake To Vacate function enables the aircraft to vacate the runway at the desired turn-off point automatically.

While technological advancements have gone a long way in the construction of the aircraft type and powering it with next-generation engines, there are also technologies within the aircraft flight deck that enable smooth and efficient operations for the pilot.

The Brake To Vacate (BTV) function allows the pilot to pre-program the aircraft (prior to landing) to vacate the runway of their destination airport using an exit point of their choice.

This helps to reduce:

- The runway occupancy time of the aircraft upon landing

- Reducing delays

- Improving operational efficiency.

Photo: Vincenzo Pace | Simple Flying

By utilizing this function, the aircraft automatically decelerates and vacates the runway at the desired point, reducing operational wear on the aircraft brakes and resulting in safer operation.

(The only other aircraft type to have this function is the Airbus A380-800).